Your Current Position: Products

HSBP-B Multichannel Side Negative Plate Side Separator AGM Machine For VRLA Battery

Environmental Protection、Stable、Low labor cost、Warning and alarm

AGM Wrapping And Stacking Machine For Medium Size VRLA Battery

Using programmable controller, the operation is stable and accurate;It is easy to operate and maintain;

HSZH-01 COS For VRLA Battery

cast and weld of medium and small lead-acid batteries and automatically slot battery groups, instead of the shortcomings of manual welding, it saves labor and material cost, features high efficiency and clean and green production.

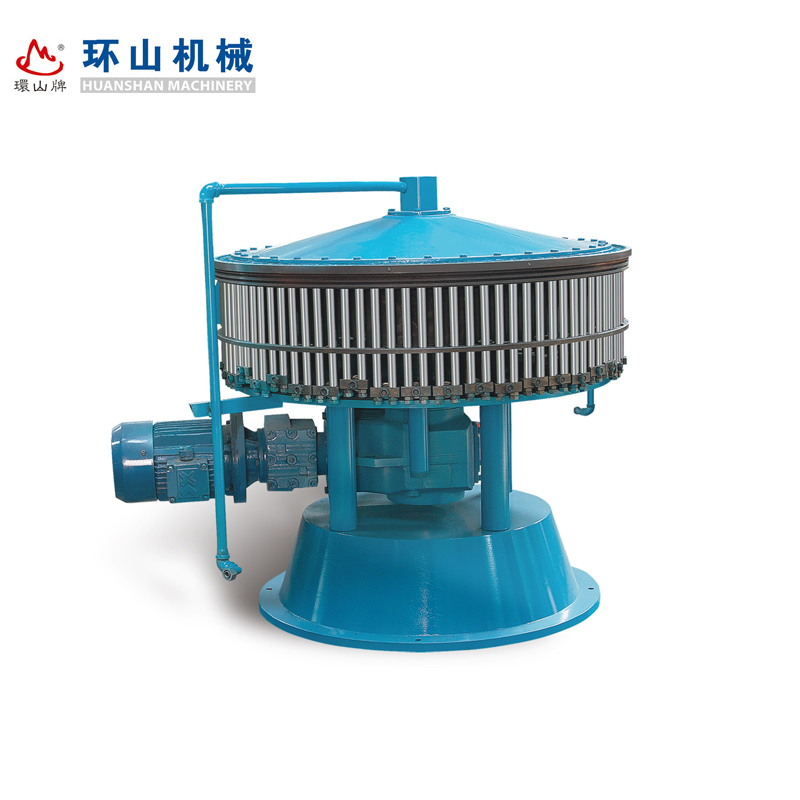

QMJB Serial Oxide Ball Mill Set

The lead oxide ball mill set adopts special bearings, instead of old supporting roller structure, which greatly improved the drive efficiency and doubled its operational life span.

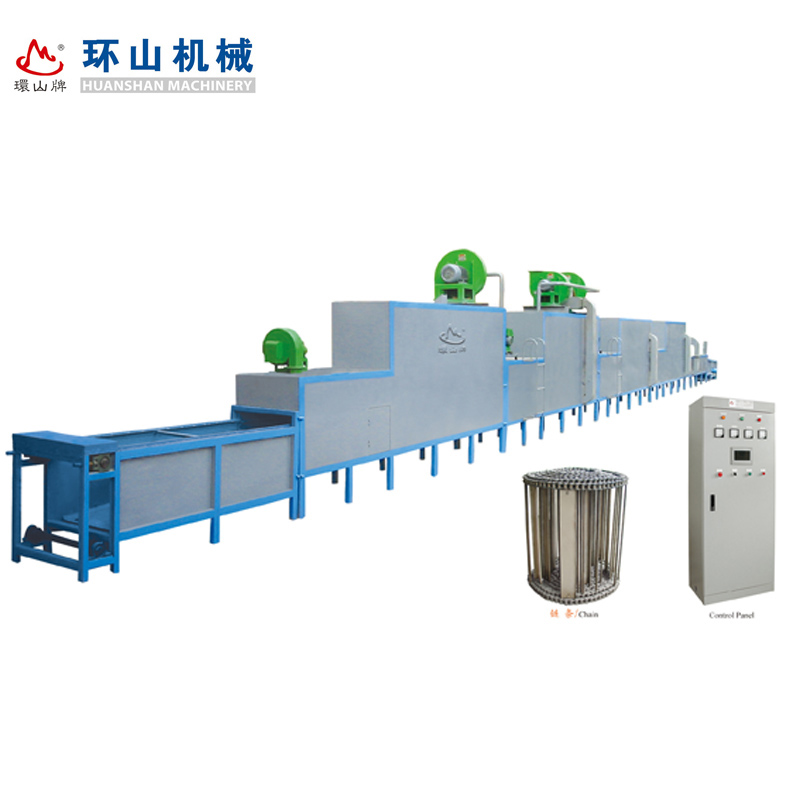

HSGG curing and drying system

Combining with many years’ practicing experiences and analyzing the advantages and disadvantages of curing and drying system produced by many manufacturers at home and abroad, we have designed HSGG curing and drying system which reached a domestic advanced level.

Plate curing and drying chamber

Plate Curing and Drying chamber is the key equipment during producing storage battery. Our HSGG-03(gas or fuel) Curing and drying chamber is a compact and intellectualized equipment.

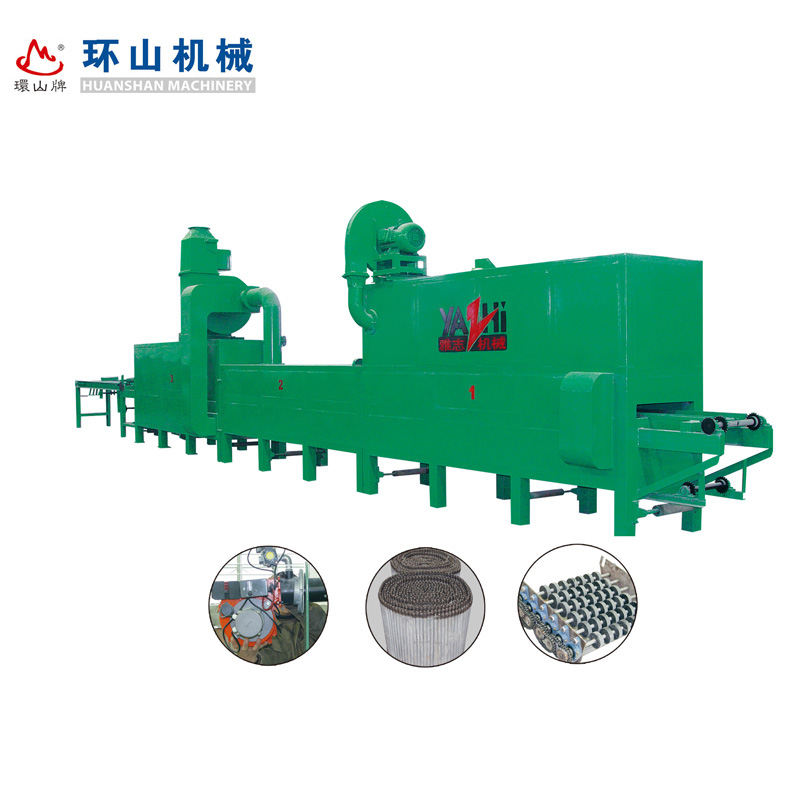

JBHG Drying Oven After Formation

The complete machines can automatically control the drying temperature according to value set in each stage of the entire course about automatic control on fuel consumption.

Small VRLA, E-Bike Battery Assembly Line

Mainly used for small VRLA battery, e-bike battery assembling, such as plate pack welding, bridge welding, case-cover epoxy curing, terminal welding ,color epoxy curing.

Plate surface drying line

It is characterized by reasonable structure, simple operations, and high productivity. It is a special machine used with the plate pasting machine.

QL Lead Dice Cutter Set

This machine set was consisted of lead melting furnace, cooling rotary disk and dicer cutter, which has merits of high output, less maintenance and easy operation. It is an ideal dicer cutter.